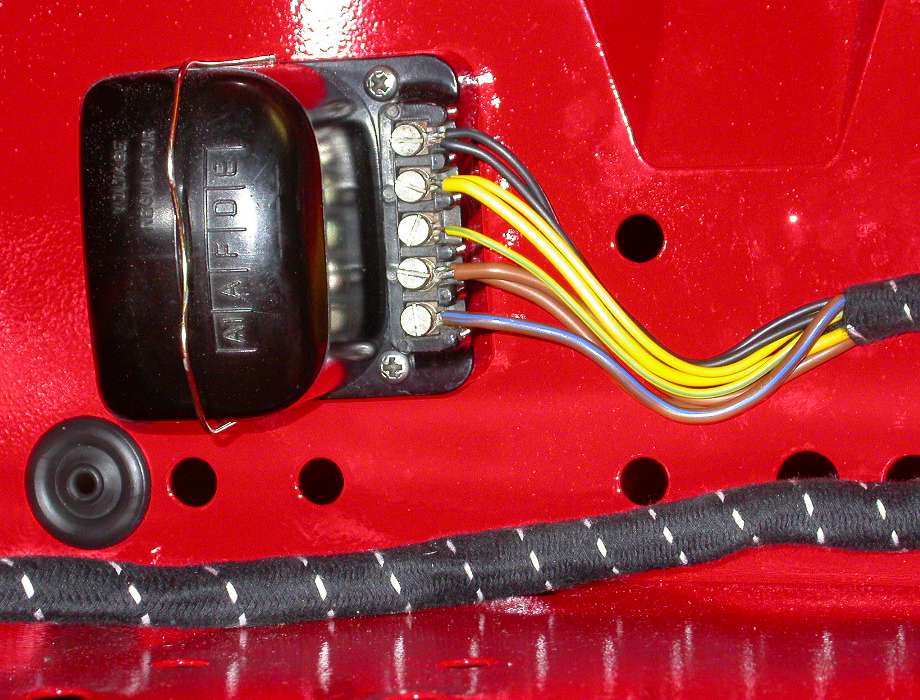

Wiring harness installation is a crucial aspect of any vehicle or machinery maintenance. It involves the assembly of wires, connectors, and terminals to ensure proper electrical connections within the system. This process is essential for the smooth operation of various electrical components, making it a fundamental skill for mechanics and technicians.

Why Wiring Harness Installation is Essential

Wiring harness installation is essential for several reasons:

- Ensures proper electrical connections

- Reduces the risk of electrical shorts and malfunctions

- Facilitates easier maintenance and troubleshooting

- Improves overall system reliability

Reading and Interpreting Wiring Harness Installation

When it comes to reading and interpreting wiring harness installations, it is important to:

- Follow the manufacturer’s instructions carefully

- Identify the correct wire colors and labels

- Use a wiring diagram or schematic for reference

- Verify connections before finalizing the installation

Using Wiring Harness Installation for Troubleshooting

Wiring harness installations can be invaluable for troubleshooting electrical problems. By following these steps, you can effectively diagnose and repair issues:

- Inspect the wiring harness for any visible damage or loose connections

- Use a multimeter to test continuity and voltage levels

- Refer to wiring diagrams to identify the root cause of the problem

- Replace or repair any faulty components within the harness

Importance of Safety

Working with electrical systems and wiring diagrams can be dangerous if proper safety precautions are not followed. Here are some important safety tips:

- Always disconnect the power source before working on electrical systems

- Use insulated tools to prevent electrical shocks

- Avoid working on wet surfaces or in damp conditions

- Wear appropriate personal protective equipment, such as gloves and goggles

Wiring Harness Installation

Step by step wiring harness install – YouTube

Trailer Wiring Harness Install

MGA wiring harness installation

Wiring Harness Diagram For Pioneer Avh 120bt – Wiring Diagram

Toyota Tacoma Wiring Harness

Trailer Wiring Harness Diagram – Cadician's Blog