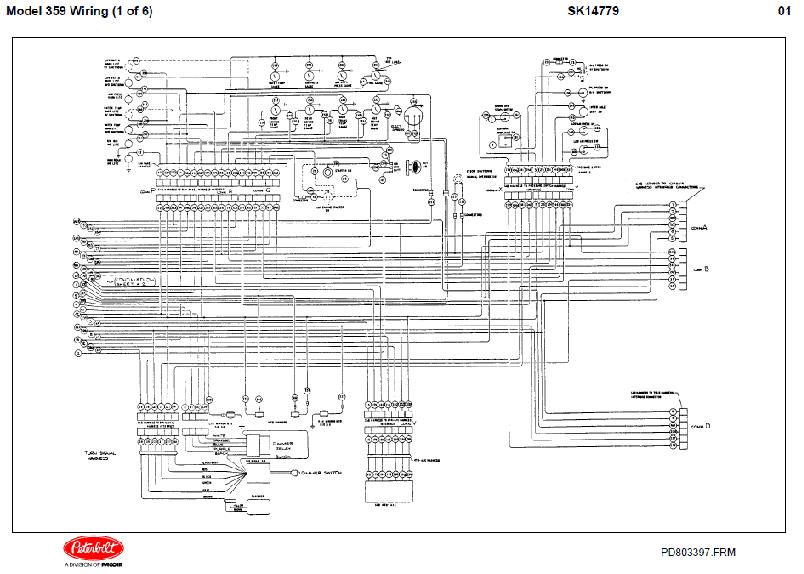

When it comes to working on diesel engines, having a good understanding of the wiring diagram is crucial. The diesel engine wiring diagram is a detailed schematic that shows the connections and electrical components in the system. It is an essential tool for mechanics and technicians to diagnose and repair electrical issues in diesel engines.

Why Diesel Engine Wiring Diagrams are Essential

Diesel engine wiring diagrams are essential for several reasons:

- Helps in understanding the electrical system of the engine

- Aids in diagnosing electrical problems

- Guides in proper installation of new components

- Ensures safety by preventing electrical shorts or fires

How to Read and Interpret Diesel Engine Wiring Diagrams

Reading and interpreting a diesel engine wiring diagram may seem daunting at first, but with some practice, it becomes easier. Here are some tips on how to effectively read and interpret wiring diagrams:

- Identify key components such as relays, fuses, connectors, and wires

- Follow the flow of the diagram from the power source to the components

- Understand the symbols and colors used in the diagram

- Refer to the legend or key for clarification

Using Diesel Engine Wiring Diagrams for Troubleshooting

Diesel engine wiring diagrams are invaluable when troubleshooting electrical problems. By following the wiring diagram, technicians can pinpoint the source of the issue and make the necessary repairs. Some common uses of wiring diagrams for troubleshooting include:

- Checking for continuity and voltage at various points in the system

- Identifying faulty components or connections

- Testing sensors and switches for proper operation

- Locating short circuits or open circuits in the wiring

Importance of Safety When Working with Electrical Systems

Working with electrical systems, including diesel engine wiring, can be dangerous if proper precautions are not taken. Here are some safety tips and best practices to keep in mind:

- Always disconnect the battery before working on the electrical system

- Use insulated tools to prevent electrical shock

- Avoid working on wet surfaces or in damp conditions

- Wear appropriate personal protective equipment, such as gloves and safety glasses

Diesel Engine Wiring Diagram

Diesel Engine Wiring Diagram – Headcontrolsystem

Diesel Ignition Switch Wiring Diagram – Headcontrolsystem

Detroit Diesel DDEC II Engine Electrical Wiring Diagrams

Perkins 4108 Wiring Diagram

diesel generator control panel wiring diagram – Generator Controllers

Cummins Comercial Marine Diesel Engine Wiring Diagram | Auto Repair